Expertise

Fundex has gained world fame over the years. With over 70 years of experience and a wide range of multifunctional foundation techniques, we are your flexible partner in every project. Below is an overview of our expertise.

Vibration-free techniques

Your title comes here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Fundex® pile

Definition

Vibration-free, soil-formed, soil-displacing concrete pile manufactured using a screw-in steel auxiliary tube.

Specifications

Dimensions pile:

Standard dimensions are:

| Shaft diameter [mm]: |

Associated drill point [mm]: |

| ø 380 | ø 450 |

| ø 460 | ø 560 |

| ø 540 | ø 660 |

Length pile:

Up to approximately 35 to 40 meters. The pile is poured to ground level. This determines the pile length from pile tip level to ground level.

Reinforcement:

The piles are provided with prefabricated reinforcement baskets. From quality aspect, they are preferably reinforced along the entire length.

Concrete:

The piles are poured on site using concrete directly from the plant. All strength classes can be applied here.

Soil mechanical bearing capacity:

NL: The bearing capacity is calculated in accordance with current EC, NEN and CUR standards.

B: The bearing capacity is calculated in accordance with current EC, NBN and CUR standards.

Methods:

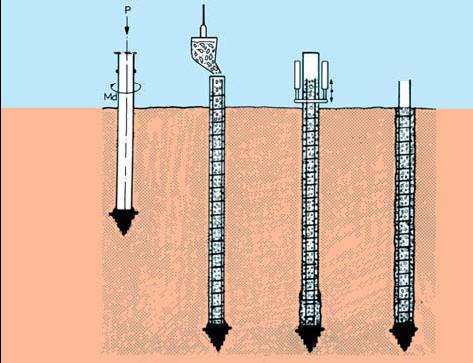

- A steel auxiliary pipe, equipped with a loose drill point, is placed at ground level;

- The tube is screwed to depth by applying axial pressure and torque;

- Upon reaching the desired pile tip level, the reinforcement is suspended in the tube;

- The tube is filled with concrete;

- The tube is pulled oscillating, leaving the drill tip behind;

- The pile is now manufactured;

- The rack can be moved to the next pole location.

Advantages:

- Vibration-free, and 100% ground displacement (no relaxation of soil or reduction of cone resistance);

- No risk of damage to adjoining properties during the manufacture of the pile;

- A large carrying capacity allowable;

- Extremely suitable as a pressure and tension pole;

- No noise pollution, like pile driving or vibration. Only noise is the drill motor;

- No soil removal. Soil is pushed away laterally.

Applicable base:

Fundex piles can be well applied in foundations of approximately 1 to 20 MPa. If one is dealing with very weak layers, it is possible to choose a system where a permanent casing is applied, such as the Fundex-combi or the Tubex pile. If one is dealing with very heavy layers, it is possible to choose a system with grout injection, such as the Fundex gi pile or the Tubex gi pile.

Brace positions:

Up to 4:1 forward and 2:1 backward.

Work space:

To perform the Fundex pile one must have a clear height and sufficient space.

Encroachments:

The piles can be installed at a distance of approximately 0.9 m perpendicular to the abutting wall. In the case of recessed corners it is of course more.

Workable racks:

Fundex F12S, F12SE, F15, F16, F2800, F3500.

Shelving dimensions:

Depends on type of racking. Most common; setup area approximately 7 x 12 m.

Rack height approximately 35 m.

Built-up weight variable from approximately 50 to 120 tons.

Fundex® combination pole

Here you will soon find information about Fundex® combi piles.

Fundex® combi pile with grout injection

Vibration-free, in-situ, soil displaced concrete pile with concrete pre-fabrication, screwed to depth by means of a steel auxiliary tube and under addition of grout injection.

Dimensions pile:

Standard dimensions are:

| Shaft diameter [mm]: | Associated drill point [mm]: |

| ø 380 (max.220x220mm) | ø 450 |

| ø 460 (max.250x250mm) | ø 560 |

| ø 550 (max.320x320mm) | ø 660 |

| ø 610 (max.350x350mm) | ø 740 |

| ø 660 (max.380x380mm) | ø 850 |

| ø 750 (max.500x500mm) | ø 950 |

A grout casing of the same diameter as the drill point diameter will be realized in the sand layers.

Length pile:

Depending on pile size and depending on pile tip, length pile can be varied. Also, pile head can be put away below working level.

Reinforcement:

The piles are provided with precast concrete piles. From quality aspect, they are provided with standard reinforcement along the entire length.

Concrete:

All strength classes can be applied here. Concrete minimum C45/55

Soil mechanical bearing capacity:

EN: The bearing capacity is calculated in accordance with current NEN and CUR standards.

The following factors can be applied here:

αp = 0.63

β = 1.0

s = 1.0

αs = 0.009

αt = 0.009

B: For questions regarding load capacity, please contact our office.

Methods:

- A steel auxiliary pipe, equipped with a loose drill point, is placed at ground level;

- The pipe is screwed to depth by applying axial pressure and torque and under the addition of grout injection;

- Upon reaching the desired pile tip level, the precast element is inserted into the tube

- The tube is filled with grout;

- The tube is pulled oscillating, leaving the drill tip behind;

- The pile is now manufactured;

- The rack can be moved to the next pole location.

Advantages:

- Vibration-free, and 100% ground displacement (no relaxation of soil or return of cone resistance);

- No risk of damage to adjoining properties during the manufacture of the pile;

- A large carrying capacity allowable;

- Extremely suitable as a pressure and tension pole;

- To be installed in very heavy soil layers;

- No noise pollution, like pile driving or vibration. Only noise is the drill motor;

- No soil removal. Soil is pushed away laterally.

- Install below grade (possibly from pontoon), so as not to create over-length on concrete column above cut-off level.

Applicable foundation:

Fundex combi piles with grout injection can be well applied in very heavy soil layers but also in very weak soil layers. Thanks to the use of a prefabricated pile core, there is no risk of a discontinuous pile shaft.

Bracing:

Due to the centering of the core, additional measures will need to be taken at piles with large bracing stands.

Work space:

To perform the Fundex pile one must have a clear height and sufficient space.

Encroachments:

The piles can be installed at a distance of approximately 0.9 m perpendicular to the abutting wall. In the case of recessed corners it is of course more.

Workable racks:

Fundex F12SE, F15, F2800, F3500 and F4800.

Shelving dimensions:

Depends on type of racking. Most common;

Setup area approximately 7 x 12 m. Shelving height max 48 m.

Built-up weight variable from approximately 63 to 210 tons.

Fundex® pile with grout injection

Vibration-free, in-ground, soil displacement concrete pile, screwed to depth by means of a steel auxiliary tube and under addition of grout injection.

Specifications

Dimensions pile:

Standard dimensions are:

| Shaft diameter [mm]: |

Associated drill point [mm]: |

| ø 380 | ø 450 |

| ø 460 | ø 560 |

| ø 540 | ø 670 |

| ø 660 | ø 840 |

A grout casing of the same diameter as the drill point diameter will be realized in the sand layers.

Length pile:

Up to approximately 35 to 40 meters. The pile is always poured to ground level. As a result, the pile length is determined from pile tip level to ground level.

Reinforcement:

The piles are provided with prefabricated reinforcement baskets. From quality aspect, they are preferably reinforced along the entire length.

Concrete:

The piles are poured on site using concrete directly from the plant. All strength classes can be applied here.

Soil mechanical bearing capacity:

NL: The load-bearing capacity is calculated in accordance with current EC, NEN and CUR standards.

B: The load-bearing capacity is calculated in accordance with the current EC, NBN and CUR standards.

Methods:

- A steel auxiliary pipe, equipped with a loose drill point, is placed at ground level;

- The pipe is screwed to depth by applying axial pressure and torque and under the addition of grout injection;

- Upon reaching the desired pile tip level, the reinforcement is suspended in the tube;

- The tube is filled with concrete;

- The tube is pulled oscillating, leaving the drill tip behind;

- The pile is now manufactured;

- The rack can be moved to the next pole location.

Advantages:

- Vibration-free, and 100% ground displacement (no relaxation of soil or reduction of cone resistance);

- No risk of damage to adjoining properties during the manufacture of the pile;

- A large carrying capacity allowable;

- Extremely suitable as a pressure and tension pole;

- To be installed in very heavy soil layers;

- No noise pollution, like pile driving or vibration. Only noise is the drill motor;

- No soil removal. Soil is pushed away laterally.

Applicable base:

Fundex piles with grout injection can be well applied in very heavy soil layers.

Brace positions:

Up to 4:1 forward and 2:1 backward.

Work space:

To perform the Fundex pile one must have a clear height and sufficient space.

Encroachments:

The piles can be installed at a distance of approximately 0.9 m perpendicular to the abutting wall. In the case of recessed corners it is of course more.

Workable racks:

Fundex F12SE, F15, F2800 and F3500.

Shelving dimensions:

Depends on type of racking. Most common;

Setup area approximately 7 x 12 m. Rack height approximately 35 m.

Built-up weight variable from approximately 63 to 120 tons.

Fundex® tension anchor with grout injection

Vibration-free soil-formed, soil displacement tension anchor, screwed to depth by means of a steel auxiliary tube and under addition of grout injection.

Specifications

Anchor dimensions:

Standard dimensions are:

| Shaft diameter [mm]: |

Associated drill point [mm]: |

| ø 250 | ø 250 |

Length of anchor:

Up to approximately 30 to 42 meters. The anchor is installed from ground level. This determines the installation length from pile tip level to ground level.

Reinforcement:

Anchors are provided with a central reinforcement bar of one length. The possibility exists to apply a bundle of bars if necessary.

Grout:

The anchors are provided in the work with a grout shell and a central grout core. Various grout compositions can be used in this process.

Soil mechanical bearing capacity:

NL: The bearing capacity is calculated in accordance with current EC, NEN and CUR standards.

B: The bearing capacity is calculated in accordance with current EC, NBN and CUR standards.

Methods:

- A steel auxiliary pipe, equipped with a loose drill point, is placed at ground level;

- The pipe is screwed to depth by applying axial pressure and torque and under the addition of grout injection;

- Upon reaching the desired pile tip level, a central reinforcement rod is inserted into the tube;

- The tube is filled with a grout mixture;

- The tube is pulled, with mixing occurring between the mixed-in-place grout shell and the grout mixture. The drill tip is left behind;

- The anchor is now fabricated;

- The rack can be moved to the next anchor location;

- After excavation, the anchor can be fitted with a head plate which is cast into the structure.

- Vibration-free, and 100% ground displacement (no ground relaxation or reduction in cone resistance)

- No risk of damage to adjoining properties during the manufacture of the pile;

- High tensile load capacity permissible;

- No noise pollution, like pile driving or vibration. Only noise is the drill motor;

- No soil removal. Soil is pushed away laterally.

- Anchor can be installed recessed.

Applicable base:

Fundex tension anchors with grout injection can be well applied in very heavy soil layers.

Brace positions:

Up to 4:1 forward and 2:1 backward.

Working space:

To perform the Fundex tension anchor, one must have a clear height and sufficient space.

Encroachments:

The anchors can be installed at a distance of approximately 0.9 m perpendicular to the abutting wall. In the case of recessed corners it is of course more.

Workable racks:

Fundex F12SE, F15, F2800 and F3500.

Shelving dimensions:

Depends on type of racking. Most common;

Shelving area approximately 7 x 12 m. Shelving height approximately 35 m.

Built-up weight variable from approximately 63 to 120 tons....

Tubex® pile

Definition

Vibration-free, soil-displacing concrete pile with permanent steel tube, screwed to depth.

Specifications

Dimensions pile:

Standard dimensions are:

| Tube diameter [mm]: |

Associated drill point [mm]: |

| ø 168 or 219 | ø 310 |

| ø 324 or 355 | ø 450 |

| ø 355 or 406 | ø 560 |

| ø 457 or 508 | ø 670 |

| ø 609 | ø 850 |

| ø 762 | ø 950 |

Length pile:

In principle, unlimited. The maximum length is generally about 30 m. The pile head can be installed either to ground level or sunken.

Reinforcement:

The piles are provided (if necessary) with prefabricated reinforcement baskets. Depending on the requirements, they are reinforced with head reinforcement or full length.

Concrete:

The piles are (possibly) provided with concrete directly from the plant. All strength classes can be applied here.

Soil mechanical bearing capacity:

NL: The bearing capacity is calculated in accordance with current EC, NEN and CUR standards.

B: The bearing capacity is calculated in accordance with current EC, NBN and CUR standards.

Methods:

- A steel pipe, equipped with a welded steel drill point, is placed at ground level;

- The tube is screwed to depth by applying axial pressure and torque;

- Upon reaching the desired pile tip level, the pile is installed;

- The rack can be moved to the next pile location; At a later stage, the steel tube will be burned off at the exact height;

- The reinforcement is inserted into the pipe;

- The tube is filled with concrete;

- The pile is now manufactured.

- Vibration-free, and 100% ground displacement (no relaxation of soil or reduction of cone resistance);

- No risk of damage to adjoining properties during the manufacture of the pile;

- Ideally suited for absorbing large compressive and tensile forces, moments and limiting deformations;

- No noise pollution, like pile driving or vibration. Only noise is the drill motor;

- No soil removal. Soil is pushed away laterally;

- Good application in very weak soil layers. Deformation of the pile shaft cannot occur here;

- Applicable as a temporary foundation pile;

- Applicable in rooms with limited height or space.

Applicable base:

Tubex piles can be well applied in bases from about 1 to 20 MPa. In places where there are very weak layers, it is possible to opt for this system. If dealing with very heavy layers, it is possible to choose a system with grout injection, such as the Fundex gi pile or the Tubex gi pile.

Brace positions:

Up to 4:1 forward and 1:1 backward. It is also possible to drill up to 3:1 "out of side".

Workspace:

The Tubex pole is applicable in both free and restricted height, or space.

Loads:

Depending on the racking, the piles can be installed at a distance of approximately 0.5 to 0.9 m perpendicular to the abutment. In the case of recessed corners, this is of course more.

Workable racks:

Fundex F10, F12S, F12SE, F15, F16, F2800, F3500.

All Tubex racks.

Shelving dimensions:

Depending on type of racking.

Shelving variable from approximately 2×3 to 9×14 m.

Height variable from approximately 2.5 to 48 m.

Built-up weight variable from about 13 to 120 tons.

Tubex® pile with grout injection

Vibration-free, soil-displacing concrete pile with permanent steel pipe, screwed to depth under the addition of grout injection.

Specifications

Dimensions pile:

Standard dimensions are:

| Tube diameter [mm]: |

Associated drill point [mm]: |

| ø 168 or 219 | ø 310 |

| ø 324 or 355 | ø 450 |

| ø 355 or 406 | ø 560 |

| ø 457 or 508 | ø 670 |

| ø 609 | ø 850 |

| ø 762 | ø 950 |

A grout casing of the same diameter as the drill point diameter will be realized in the sand layers.

Length pile:

Basically unlimited. The pile head can be installed either to ground level or recessed.

Reinforcement:

The piles are provided (if necessary) with prefabricated reinforcement baskets. Depending on the requirements, they are reinforced with head reinforcement or full length.

Concrete:

The piles are (possibly) provided with concrete directly from the plant. All strength classes can be applied here.

Soil mechanical bearing capacity:

EN: The bearing capacity is calculated in accordance with current NEN and CUR standards.

The following factors can be applied here:

ap = 0.63

ß = 1.0

s = 1.0

ax = 0.009

at = 0.009

B: For questions regarding load capacity, please contact our office.

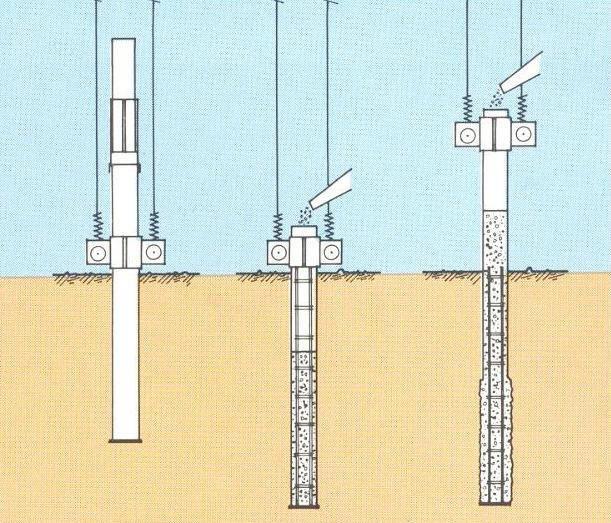

Methods:

- A steel pipe, equipped with a welded steel drill point, is placed at ground level;

- The pipe is screwed, under the addition of a grout mixture, to depth by applying axial pressure and torque;

- Upon reaching the desired pole point level, the pile is installed;

- The rack can be moved to the next pole location;

- At a later stage, the steel tube will be burned off at the exact height;

- The reinforcement is inserted into the pipe;

- The tube is filled with concrete;

- The pile is now manufactured.

Advantages:

- Vibration-free, and 100% ground displacement (no relaxation of soil or reduction of cone resistance);

- No risk of damage to adjoining properties during the manufacture of the pile;

- A very large load capacity allowable;

- Ideally suited for absorbing large compressive and tensile forces, moments and limiting deformations;

- No noise pollution, like pile driving or vibration. Only noise is the drill motor;

- No soil removal. Soil is pushed away laterally;

- Applicable in almost all soil types;

- Applicable in rooms with limited height or space;

- Ability to pierce masonry, skim concrete and existing wood piles.

Applicable foundation:

Tubex piles with grout injection can be well applied in very heavy foundations with taper values up to about 80 MPa. In places where there are very heavy layers, it is possible to opt for this system as the pile tip level can be guaranteed. In case of any doubts regarding the feasibility, please contact the office.

Brace positions:

Up to 4:1 forward and 1:1 backward. It is also possible to drill up to 3:1 "out of side".

Workspace:

The Tubex pile with grout injection is applicable in both free and restricted height, or space.

Loads:

Depending on the racking, the piles can be installed at a distance of approximately 0.5 to 0.9 m perpendicular to the abutment. In the case of recessed corners, this is of course more.

Workable racks:

Fundex F10, F12S, F12SE, F15, F16, F2800, F3500.

All Tubex racks.

Shelving dimensions:

Depending on rack type.

Shelving space varaibel from approximately 2×3 to 9×14 m.

Height from approximately 2.5 to 48 m.

Built-up weight variable from approximately 13 to 120 tons.

Supra® pile

Here you will soon find information about Supra® piles.

Twin® pile

Vibration-free applied tubular pile wall, fabricated using screw-in permanent inserted steel pipe and fitted with an intermediate shelf with grout casing.

Specifications

Wall dimensions:

Standard dimensions are:

| Tube diameter [mm]: |

Associated drill point [mm]: |

| ø 406 | ø 520 |

| ø 508 | ø 620 |

| ø 609 | ø 720 |

| ø 711 | ø 820 |

| ø 914 | ø 1020 |

A grout casing of pipe diameter + 100 mm' will be realized in the sand layer.

Wall depth:

Up to approximately 35 to 40 meters. The wall is always installed from ground level.

This determines the depth from pile tip level to ground level.

Reinforcement and concrete:

The wall is installed with open tubes as standard. Because of this, the wall will be unreinforced. However, reinforcing and pouring the pipe is possible.

The piles can then be provided with prefabricated reinforcement baskets.

All strength classes can be used for the concrete.

Soil mechanical bearing capacity:

NL: The bearing capacity is calculated in accordance with current EC, NEN and CUR standards.

B: The bearing capacity is calculated in accordance with current EC, NBN and CUR standards.

Methods:

- Two steel tubes, fitted with welded steel drill teeth, are placed at ground level;

- The pipes are simultaneously screwed, under the addition of a grout mixture, to depth by applying axial pressure and torque;

- Upon reaching the desired pile tip level, the intermediate shelf between the two tubes is vibrated or pressed into the ditches;

- Part of the wall is now fabricated;

- The drilling rig can be moved to the next pile location.

Advantages:

- Vibration-free, and ground-neutral (no ground relaxation or reduction in cone resistance);

- No risk of damage to adjoining properties during the fabrication of the wall;

- Horizontal rigidity due to use of tube profile very high, often no horizontal anchoring needed anymore;

- The grout injection and the intermediate board create a virtually watertight joint;

- No noise pollution, like pile driving or vibration. Only noise is the drill motor;

- No soil removal. Soil is pushed away laterally.

Applicable foundation:

The Twin pile with grout injection can be well applied in foundations up to about 50 MPa. In places where there are very heavy layers, it is possible to choose this system as the pile point level can be guaranteed.

Bracing:

Is in principle possible.

Work space:

To perform the Twin Pole, one must have a clear height and sufficient space.

Encroachments:

The tubular pile wall can be installed at a distance of approximately 0.9 m perpendicular to the abutting wall. In the case of recessed corners it is of course more.

Workable racks:

Fundex F12SE, F15, F2800, F3500.

Shelving dimensions:

Depends on type of racking. Most common; setup area approximately 7 x 12 m.

Rack height approximately 35 m.

Built-up weight variable from approximately 63 to 120 tons.

Born tube pole

Here you will soon find the information about the drilled tube pole.

Tubed bore pole

Here you will soon find more information about our tubular bore pole

Walls

Here you will soon find information about walls.

Combi piles

Here you will soon find information about combi piles.

Piling & vibrating techniques

Your title comes here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Vibrex® pile

Definition

Soil-formed, soil-displaced concrete pile made using a pile-driven steel auxiliary tube.

Specifications

Dimensions pile:

In principle, all external pipe diameters are applicable. The most common tube diameters are: ø273, ø324, ø356, ø406, ø456, ø508, ø556, ø610, ø711. The size of the base plate is generally 40 to 50 mm larger than the selected tube diameter.

Length pile:

Up to approximately 35 to 40 meters. The pile is poured to ground level. This determines the pile length from pile tip level to ground level.

Reinforcement:

The piles are provided with prefabricated reinforcement baskets. From quality aspect, they are preferably reinforced along the entire length.

Concrete:

The piles are poured on site using concrete directly from the plant. All strength classes can be applied here.

Soil mechanical bearing capacity:

NL: The bearing capacity is calculated in accordance with current EC, NEN and CUR standards.

B: The bearing capacity is calculated in accordance with current EC, NBN and CUR standards.

Methods:

- A steel auxiliary pipe, equipped with a base plate, is placed at ground level;

- The tube is inserted by piling on the top of the tube;

- Upon reaching the desired pile tip level, the reinforcement is suspended in the tube after checking that the tube is dry and free of soil;

- The tube is filled with concrete mortar;

- The tube is pulled by vibrating with a vibrating block or (ring) vibrator;

- The pile is now manufactured;

- The rack can be moved to the next pole location

Advantages:

- Good application in erratic soil layers. Piling may be used if no bounce has yet been achieved.

- Quick Process;

- A large carrying capacity allowable;

- Extremely suitable as a pressure and tension pole;

- High degree of compaction of concrete by vibratory drawing;

- No soil removal. Soil is pushed away laterally;

- No extreme inconvenience from supply materials;

- Applicable at low temperatures;

Applicable base:

Vibrex piles can be used in almost all bases. If one is dealing with very weak layers, it is possible to choose a system where a permanent casing is applied, such as a precast concrete element or a permanent steel pipe.

Brace positions:

Up to 4:1 forward and 2:1 backward.

Work space:

To perform the Vibrex pile one must have a clear height and sufficient space.

Encroachments:

The piles can be installed at a distance of approximately 0.9 m perpendicular to the abutting wall. In the case of recessed corners it is of course more.

Workable racks:

Fundex F12S, F12SE, F15, F16, F2800, F3500.

Shelving dimensions:

Depends on type of racking. Most common; setup area approximately 7 x 12 m. Rack height approximately 35 m.

Built-up weight variable from approximately 50 to 120 tons.

Super Vibrex® pile

Soil-formed, driven, soil-displaced concrete pile, fabricated using a pile-driven inserted steel pile tube.

Specifications

Dimensions pile:

In principle, all external pipe diameters are applicable. The most common pipe diameters are: ø273, ø324, ø356, ø406, ø456, ø508, ø556, ø610, ø711.

The foot diameters can be made 50 cm larger than the pipe diameters in relation to the base.

Length pile:

Up to approximately 35 to 40 meters. The pile will be jettisoned to ground level.

Reinforcement:

The piles are provided with prefabricated reinforcement baskets. From quality aspect, they are reinforced along the entire length.

Concrete:

The piles are poured on site using concrete directly from the plant. All strength classes can be applied here.

Soil mechanical bearing capacity:

NL: The bearing capacity is calculated in accordance with current EC, NEN and CUR standards.

B: The bearing capacity is calculated in accordance with current EC, NBN and CUR standards.

Methods:

- A steel auxiliary pipe, equipped with a base plate, is placed at ground level;

- The tube is inserted by piling on the top of the tube;

- Upon reaching the desired pile tip level, the reinforcement is placed in the pipe after checking that the pipe is dry and free of soil;

- The tube is filled with concrete mortar

- Depending on the pile base to be made, the pile tube is raised over a limited height using a ring vibrator;

- The tube is backfilled with concrete and hermetically sealed at the top, which is then driven back to just above the pile tip level;

- The tube is then fully retracted, forming the final pile .

- The rack can be moved to the next pole location.

- Good application in erratic soil layers;

- Quick Process;

- High load-bearing capacity allowable even in weak soil layers;

- Extremely suitable as a pressure and tension pole;

- High degree of compaction of concrete by vibratory drawing.

- No soil removal. Soil is pushed away laterally;

- No extreme inconvenience from supply materials.

Applicable base:

SuperVibrex piles can be used in virtually all bases.

Brace positions:

Up to 4:1 forward and 2:1 backward.

Work space:

To perform the SuperVibrex pile one must have adequate clearance height and space.

Encroachments:

The piles can be installed at a distance of approximately 0.9 m perpendicular to the abutting wall. In the case of recessed corners it is of course more.

Workable racks:

Fundex F12S, F12SE, F15, F16, F2800, F3500.

Shelving dimensions:

Depends on type of racking. Most common; setup area approximately 7 x 12 m. Rack height approximately 35 m.

Built-up weight variable from approximately 50 to 120 tons.

Prefab pile

MV pile

HP profiles

Cast tube pole

Cupped tube pole

Gravel Post

Sandpile

Other techniques

Your title comes here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Born multi-shafts®

Introduction:

Fundex has been building shafts of both concrete and steel for various purposes for many years. These shafts are built for both private and industrial purposes. The function of the shafts varies from foundation to purification and storage of water. Some examples are:

- Parking shafts (SMART-CAREX)

- Heavy foundation for bridges or buildings (CALEX)

- Collection and storage of water (BUFFEX).

- Intermediate storage for process waste (HYDREX)

- A source for extracting water (PUREX).

- Effluent treatment reservoir (STOREX).

- Safe reservoir for storage of liquids

Anchors

Pre-drill

Quality control

Your title comes here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Static tests

(push, pull; horizontal)

Ultrasonic testing

(integrity)

Dynamic tests

(print)

we are happy to help you !